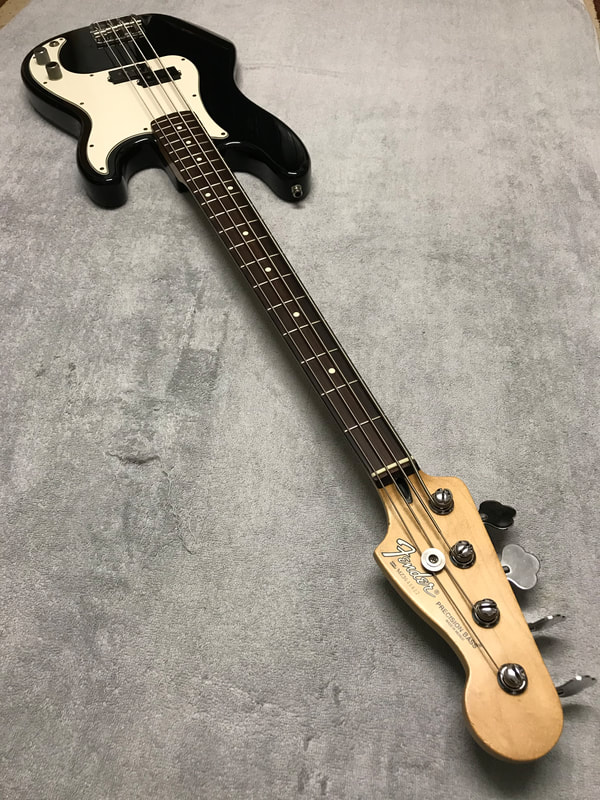

| This month has been another great month in the workshop, with some lovely guitars through that we've been lucky enough to work on. Some of the guitars that just missed out on a blog post, a lovely 7 string Ibanez in for a setup for drop tuning, an ace Fender stratocaster along with some Gibson Les Pauls needing full setups along with some other TLC! We've never too busy to work on your guitar/bass so please get in touch if you need any repairs, customisations or restoration work! |

|

0 Comments

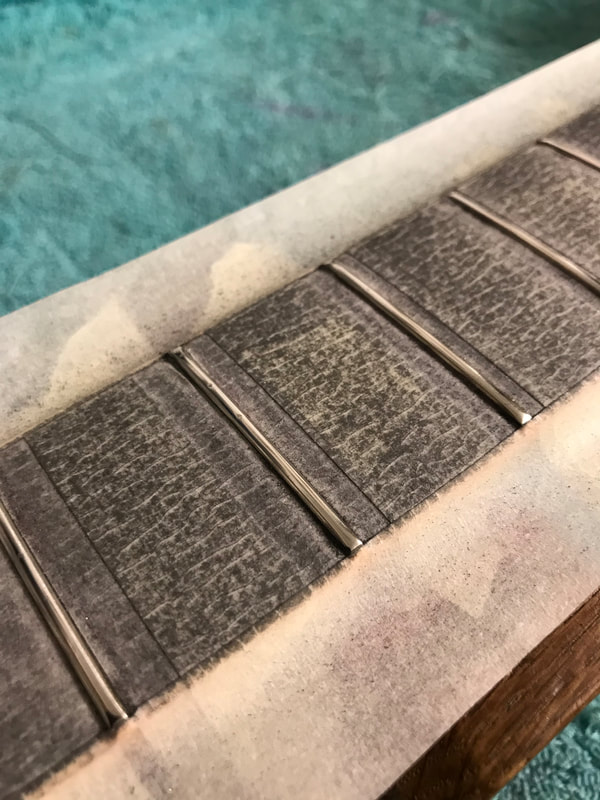

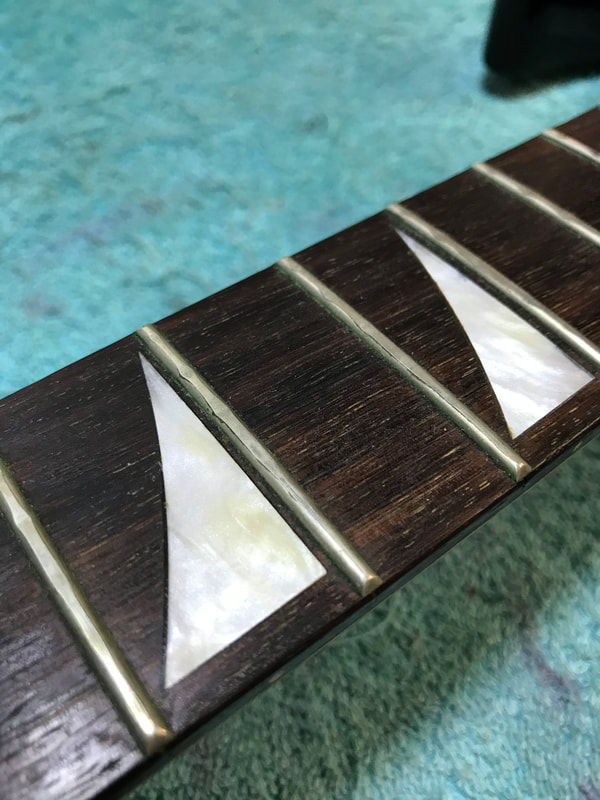

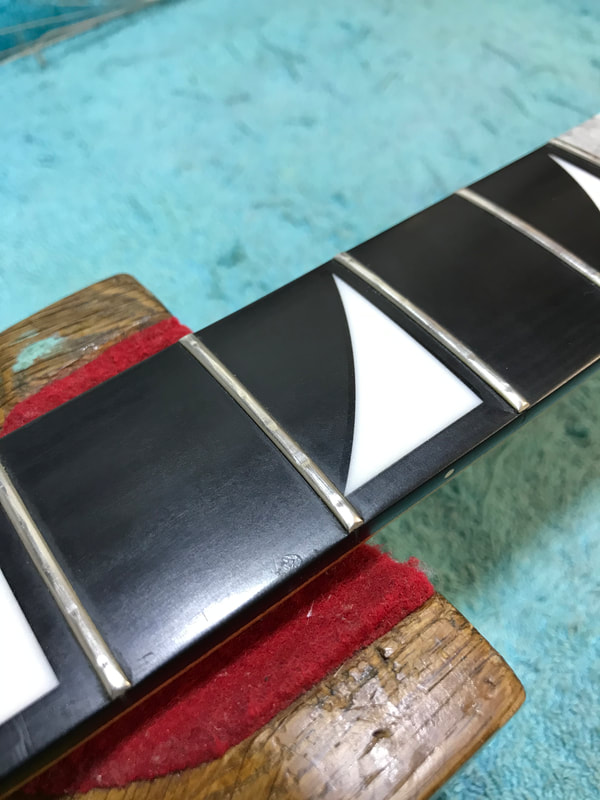

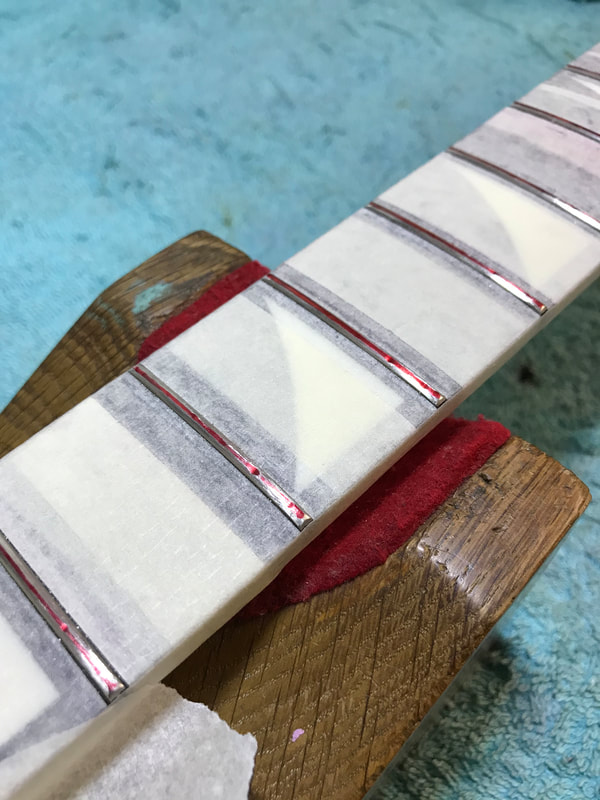

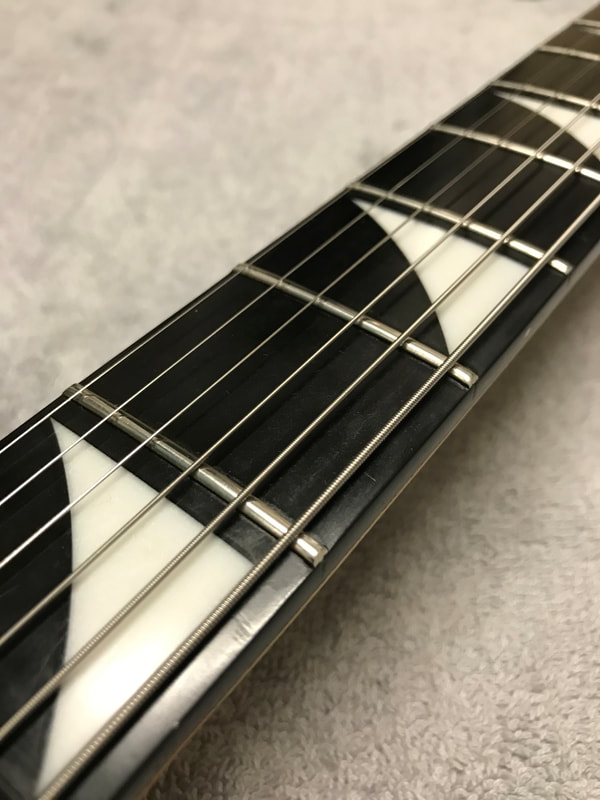

This stunning early 90’s Les Paul was recently in the workshop for a fret recrown and hand fret polish, along with a new set up pickups fitted! The frets has started to wear down after years of use, although not as bad as some of the guitars that are brought in, but the earlier fret wear is sorted, the better the result. The customer decided to have the work done rather than leave it. When there is fret wear, the string doesn't intonate as well on the fret, so the player then tends to press the string down harder to get a clear note. This causes the fret to wear even faster. Ideally the best thing is to catch the fret wear before the dips/dents in the frets become so deep, they affect the top level of the frets. After the recrown, you can see the thin marker line that preserves the top level of the frets After the hand fret polish, the shine and smoothness has returned to the frets! With all the fretwork complete, the new uprated Gibson pickups were fitted before the guitar was ready for the customer!

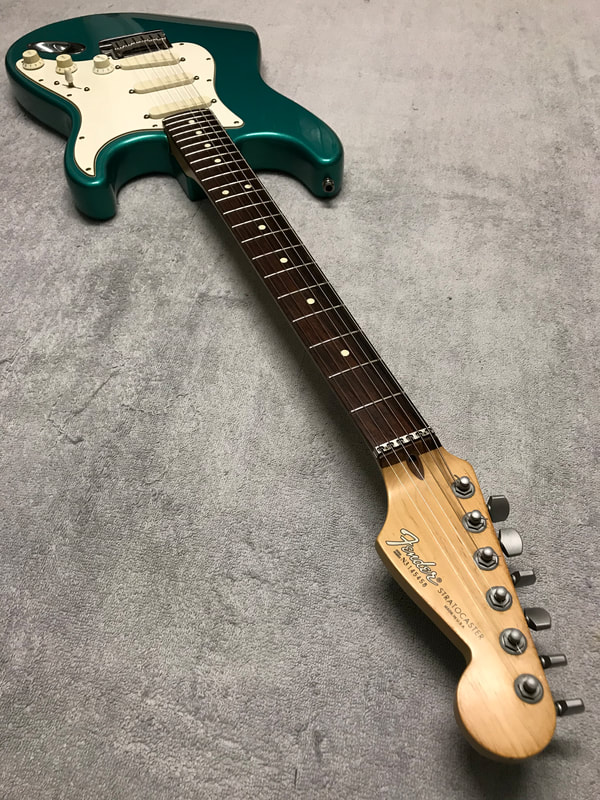

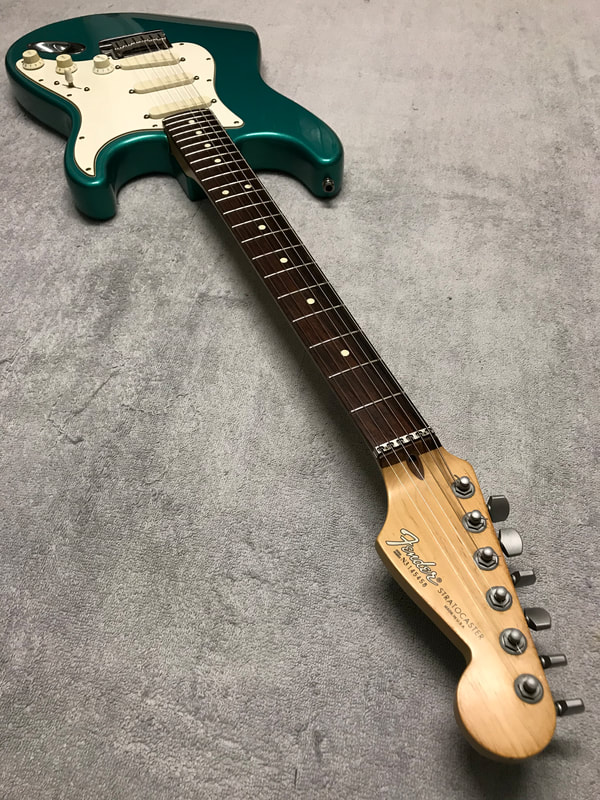

This lovely rare Caribbean Mist coloured Fender Stratocaster was recently in the workshop for a setup, and a small amount of work to the scratchplate, to allow the tremolo to function correctly! The scratchplate was overlapping the edge of the tremolo, stopping the tremolo from freely moving. So the scratchplate was worked by hand until enough space was created to allow the tremolo to freely move!

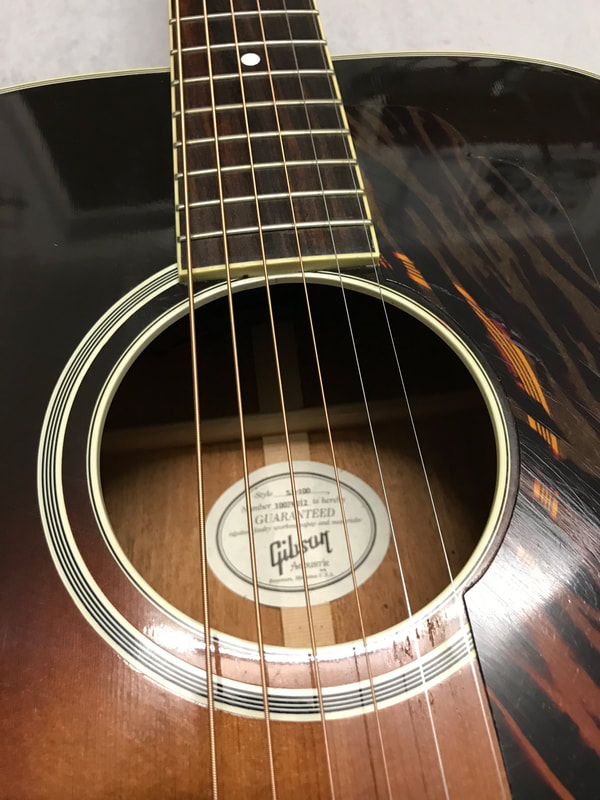

Once the scratchplate was sorted the guitar was setup ready for the customer to enjoy! This lovely Gibson SJ100 acoustic was in the workshop to have a new hand cut bone saddle fitted! The original saddle had worn due to heavy gigging, the deep slots eventually had started snapping strings! The bone saddle as it’s hand shaped to fit, matching the original shape. Once the new bone saddle was finished, the guitar was restrung and ready to go back out on the road!

The frets marked up before the recrown, you can clearly see the wear. The tops of the frets were marked so the recrowning process left the tops untouched, preserving the level of the frets. After the recrown, the majority of the fret wear has been removed. The next step was hand polishing the frets to a high smooth shine. After the hand fret polish, the guitar was restrung and setup with the new string gauge before being ready for the customer to collect!

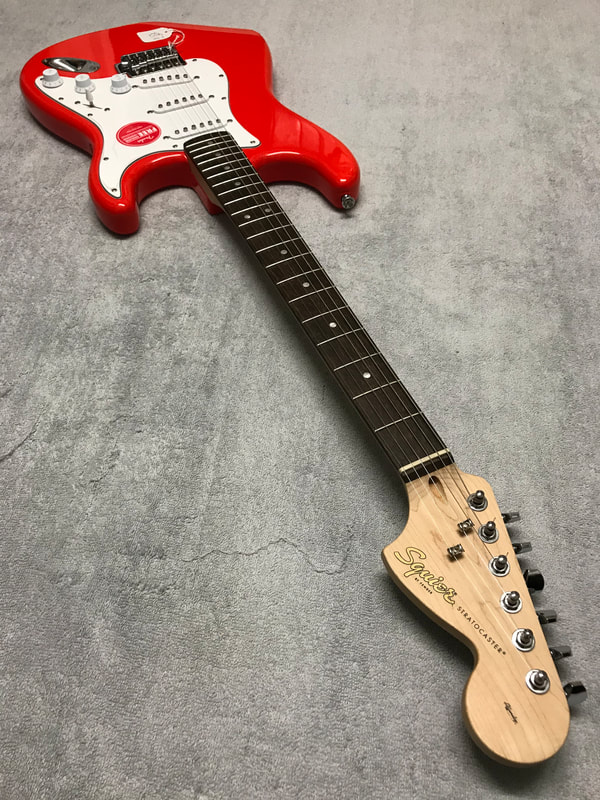

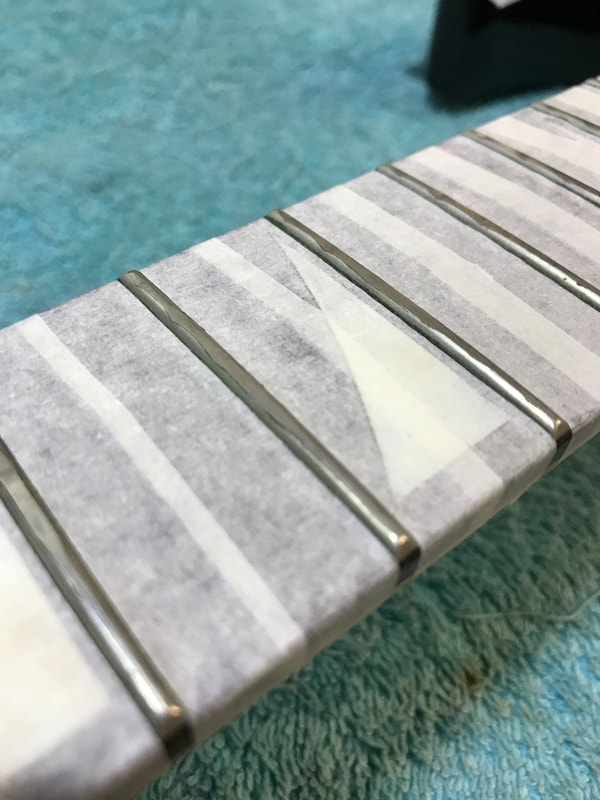

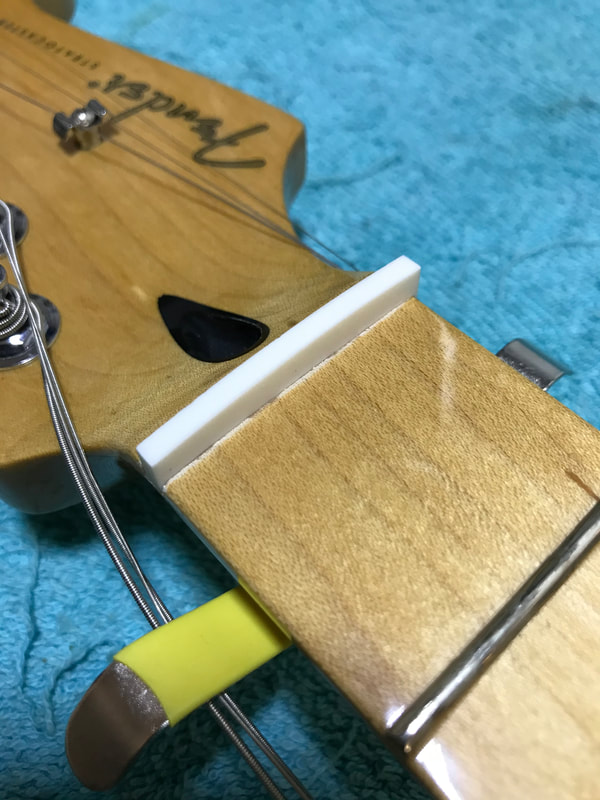

This ace Fender Stratocaster was recently in the workshop to have a new hand cut bone nut fitted, replacing the incorrect spaced one! The customer had already positioned the nut to make the string spacing on the edges of the board correct, you can see from the gap on the treble side how much it was out. The original nut spacing was slightly incorrect plus the string positioning on the fingerboard was incorrect. The correct string spacing was calculated and marked. The new nut being test fitted during its shaping, the customer had also removed the lacquer edge when he moved the original nut, this too will be sorted as part of the repair. During the slot cutting process, final slot depth is set once the nut has been glued in.

All finished with the strings on and some lacquer applied to blend it in This cool Gibson Les Paul Robot Guitar was in the workshop for a setup!

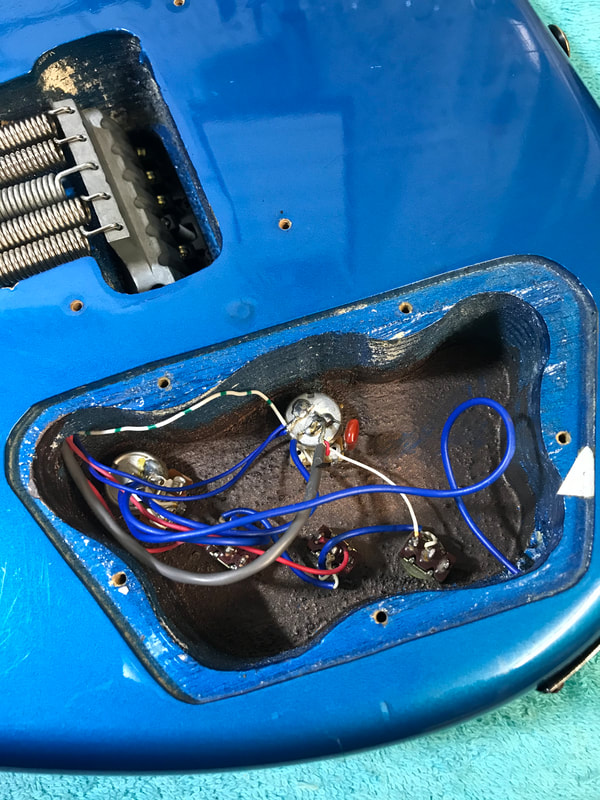

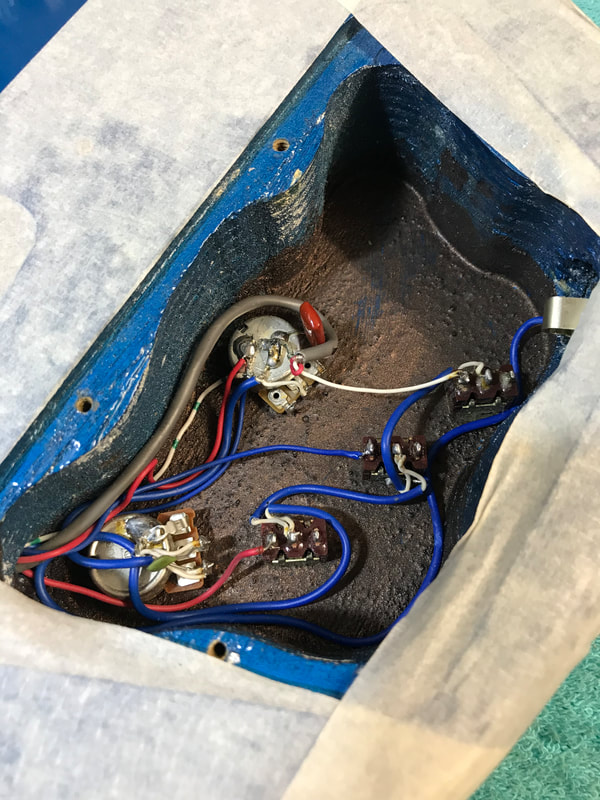

The guitars were limited to a 4,000 worldwide production, with autotuners made by Tronical! This was one of the first two that were brought into the UK when they first went on sale! This cool 80’s Vester was in the workshop for a restoration! The work included sorting the wiring, fitting new locking machineheads, hand making a custom trussrod cover along with recrowning and hand polishing the frets! The trussrod cover was definitely not original, had our suspicions it was from an old Eko acoustic. It was a bit like Swiss cheese under the cover! A template was cut for the new cover, hiding the unwanted holes plus in the style of an 80’s guitar. We used plastic from a used scratchplate to match in with the wear on the ages headstock. The new hand cut cover made and fitted! The wiring before and after, complete with unwanted out of phase pickups and a crossthread jacksocket. After sorting the pickup phasing, fitting a new switchcraft jacksocket and giving the wiring a bit of a tidy.

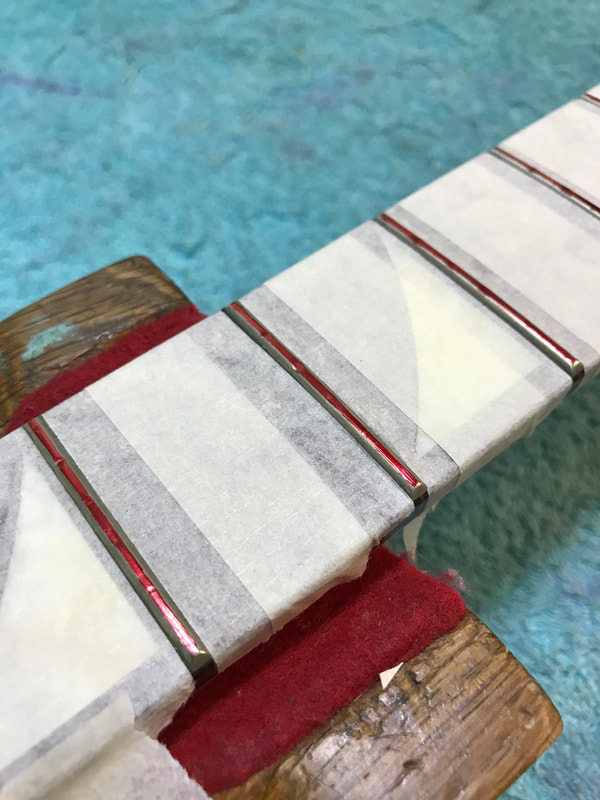

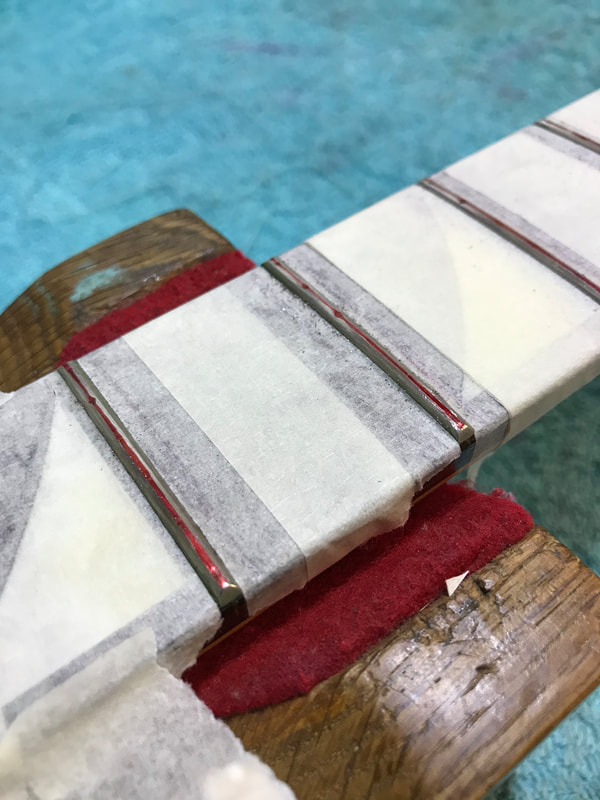

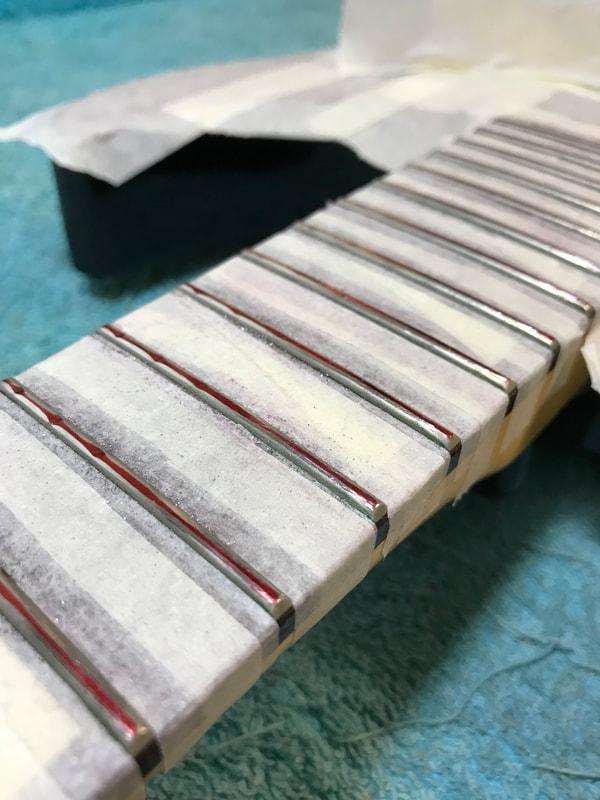

The frets were worn for years of use and needed a recrown to give playablity back into the frets.

After the recrown, most of the fretwear was removed but the level of the frets remained untouched. After the hand polish the frets were restored to a high shine. With all the work complete, the guitar was setup and ready to gig! |

Lewis DurtnallHi, I'm Lewis, Ive been repairing guitars since 2004, I learnt my craft at Totnes School of Guitar Making! Archives

December 2022

Categories |

RSS Feed

RSS Feed