| It's been a busy month in the workshop with some major projects keeping us busy. Find details of these in our recent posts. Other highlights include a 1980's Japanese Fender Telecaster haivng Bare Knuckle Pickups fitted, a dulcimer in for a restring and tlc, along with a rare Dean Dime Razor Flying V bass! We're never too busy to repair/customise/restore your guitar or bass so please get in touch and we can arrange booking you in! |

|

0 Comments

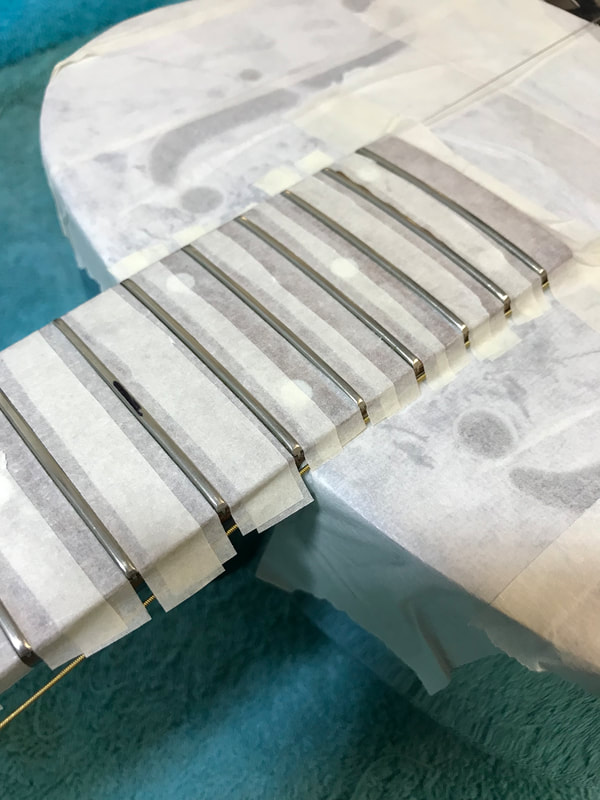

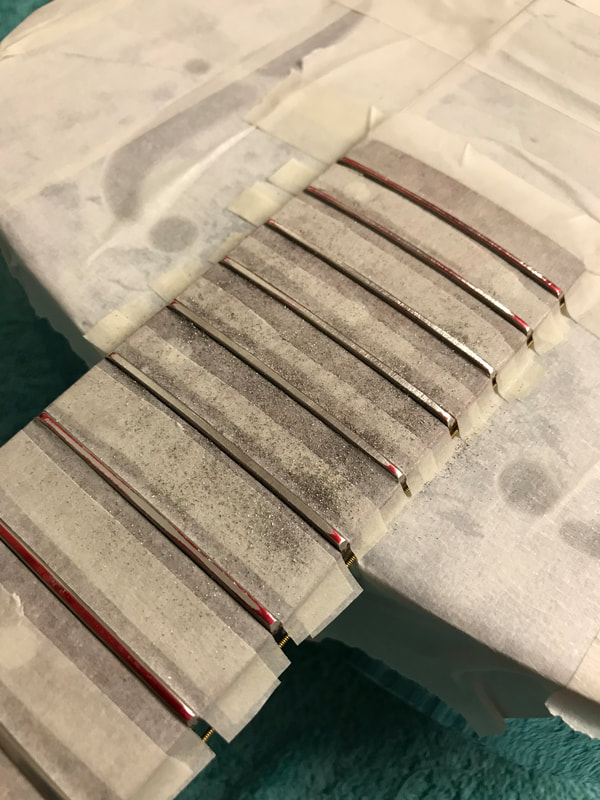

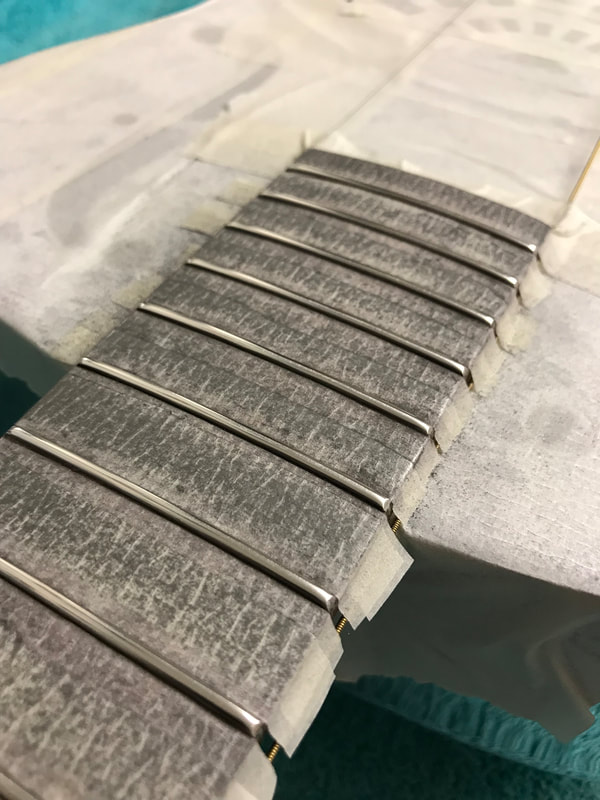

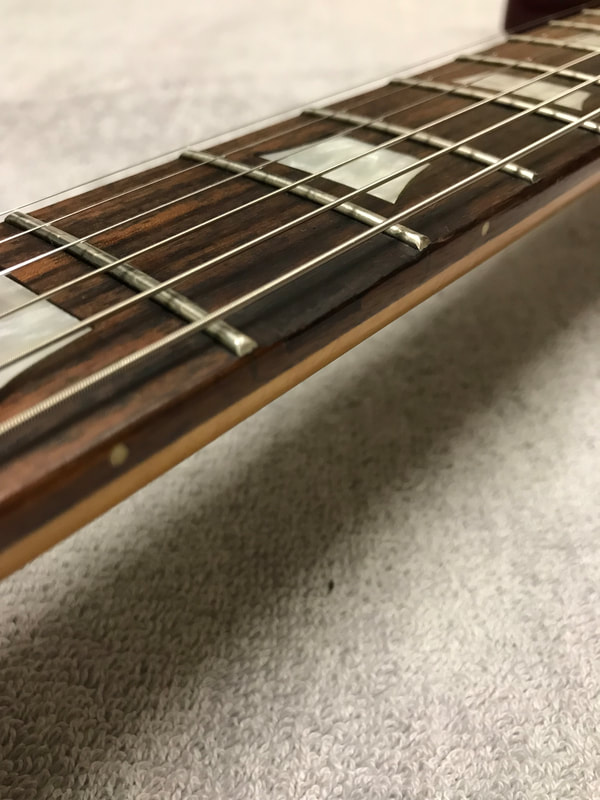

This lovely Dobro Resonator was recently in the workshop for a new hand cut bone nut & maple saddle, fret level and hand fret polish along with a setup! The upper frets were very uneven, causing dead notes and a lot of buzz. The customer has put a black sharpie mark so indicate where the problems began. After confirming the uneven frets with a straight edge, the decision was made to level the upper frets. After the upper frets were levelled, all the frets were recrown and hand polished to make all the frets feel fresh and smooth The customer wanted two new saddles made, so he had the option for slide if he wanted. This photo shows the maple blank, the two new saddles and the original saddle Fitting of the new saddle, some work was needed to be done on the biscuit to improve the tone transferal from the strings to the cone The saddle set to it’s required height, it was stained black to match the biscuit, the metal over the saddle was gently straighten too, as it had been badly buckled by its previous owner Hand cutting and shaping the new bone nut This was an opportunity to improve the fit of the nut compared to the factory fitted one With all the work complete and the guitar setup, the tone of the guitar was transformed and ready for the customer to collect.

This lovely early 90’s custom shop Warwick Streamer was brought in for a complete overhaul, All the ageing gold hardware was replaced with new black hardware, the MEC pickups and circuit was replaced with Bartolini pickups and a Darkglass Tone Capsule active preamp, Due to keeping the bass factory parts and custom active circuit plus replacement LED fretboard electronics needed, the parts were sourced from Germany or the USA! The bass when it was brought in, with worn gold hardware and the factory fitted MEC pickups. The gold evo frets were hand polished along with the brass adjustable nut. The cavity for the pickups were painted black before the new pickups were fitted, and a new LED toggle switch and battery terminal were fitted for the LED fret marker inlays.

With all the hardware changed, frets polished, the new pickups and active circuit fitted, the bass was restrung and setup before being ready for the customer to collect!

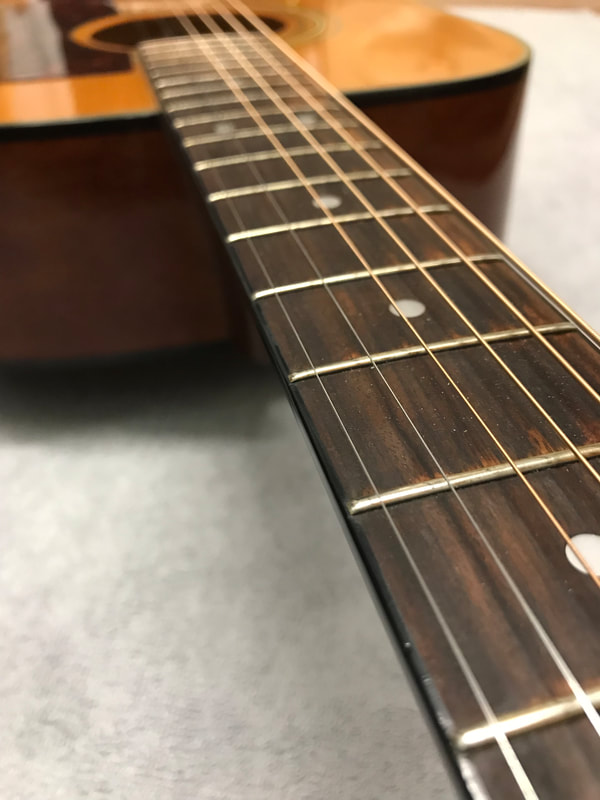

This cool and rare Epiphone M-3 was recently in the workshop for a restoration after it had an accident falling down a flight of stairs! Amazingly it took the fall very well, with a broken machinehead and a nasty chip in the fretboard being the worst of the damage! We restored it back to a very playable guitar including hand cutting and fitting a rosewood insert into the fingerboard along undoing some poor setup work from another guitar tech! A small insert of rosewood was selected then hand cut to fit the slot, with the colour and grain matching up as close as possible. The insert was then glued in and hand worked down to fit, blending into the rest of the fingerboard The guitar also suffered from an incorrect neck angle, a previous guitar techs solution was the leave a gap between the neck and the body, this opened up more in the fall. The neck was retightened after we made a maple shim for the neck, setting the correct angle and improving the tone from the gap left by the previous guitar tech New locking machine heads fitted, electronics serviced and with an low players action the guitar was ready to go

This lovely Lakland bass was in to have it’s active electronics sorted as well as an ultra low setup!

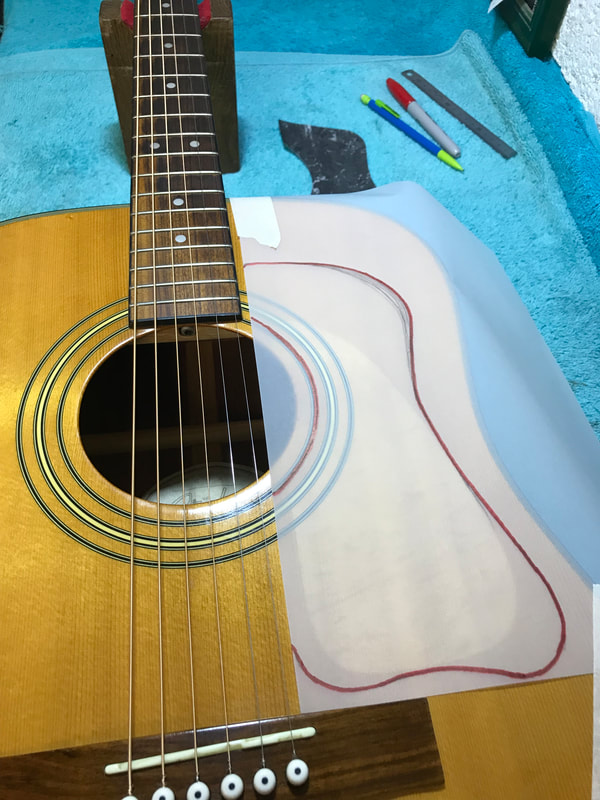

This cool 20+ year old Fender acoustic was recently in for a restoration, the customer loved the guitar, but it had become very tired and was in need of a refresh. The work involved a new hand cut bone nut and saddle, new tusq bridge pins, new Gotoh machineheads, a hand fret polish, setup and a new custom scratchplate in the style of a Gibson one!

The plastic nut and saddle were replaced with hand cut and shaped bone. This is a noticable upgrade from the plastic ones, increasing tone transference from the strings. The photos below show some stages of the process. As it turned out when the saddle was removed, it had previously been shimmed. There would be no need for this as the new bone saddle was set to the height of the action. The worn machineheads also were replaced with Gotoh machineheads, a definite upgrade from the factory fitted ones

The first step of making a custom scratchplate is marking out the shape. In this case, the new scratchplate had to cover the shape of the old one, which was a different colour due to the aging of the guitar. Once the template shape was determined, the template is transferred onto a blank sheet of scratchplate plastic, where it is cut and shaped. The final stage is the fitting on the guitar, carefully ensuring the position is correct while the adhesive backing is stuck down. With all the work done, the guitar was ready for the customer to enjoy for many more years to come!

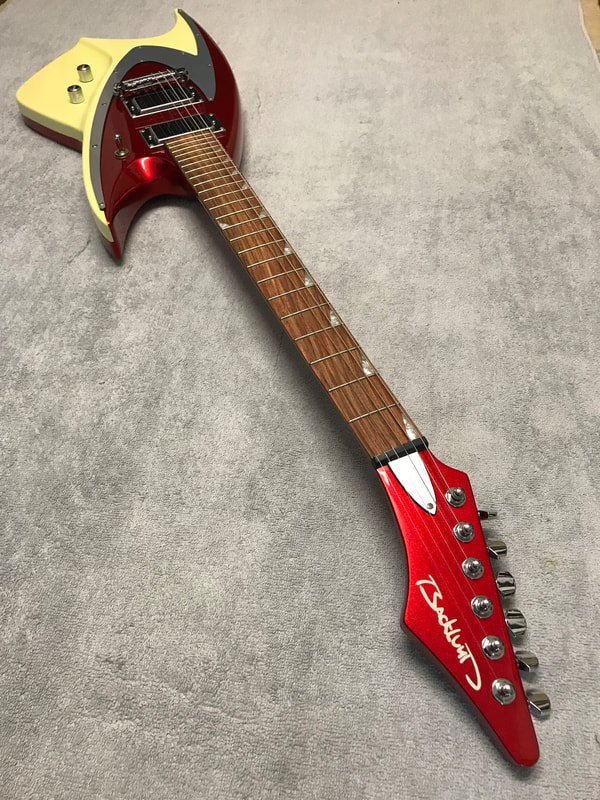

This unusual brand new Backlund guitar was recently in to have locking strap buttons fitted, a minor job, but the guitar is just too cool not to share!

|

Lewis DurtnallHi, I'm Lewis, Ive been repairing guitars since 2004, I learnt my craft at Totnes School of Guitar Making! Archives

December 2022

Categories |

RSS Feed

RSS Feed