| As normal we've been busy in the workshop with some amazing guitars through our door, so much so we're a bit behind uploading all the photos on our facebook page! Some highlights of the recent guitars through the workshop are below. Please get in touch if your guitar needs repairing and we'll be happy to help and get your guitar to it's playing best! Happy Playing! |

|

0 Comments

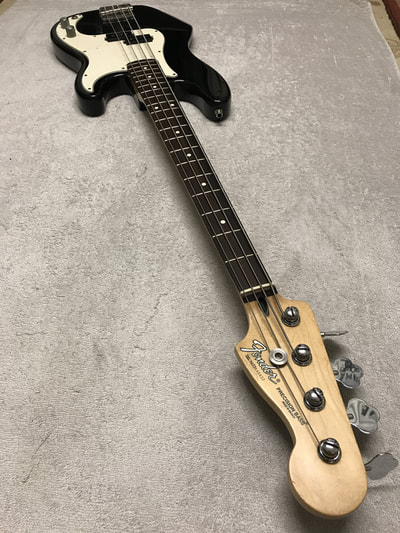

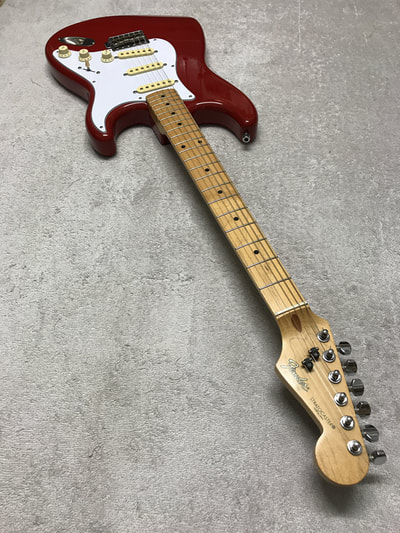

The first step was carefully removing the frets after scalping the excess lacquer off the frets, so there would be no lacquer chips when the frets were removed. The new frets were then cut and accurately hammered in one at a time The new frets in the board, the overhang tang has been removed, the next step is a rough level of the frets, only a few passes of the file is needed if the frets have been installed correctly. The next step, the neck is refitted and re masked up, then the guitar is restrung to string tension before the second accurate levelling can be done. This too doesn't remove a lot of the fret, just the high spots, to allow completely level frets for a lower action. After the levelling, you can see the fret dust from the high areas of the board, with the strings on, the guitar is regularly play tested at this point to ensure the frets are even. The next step is fret recrowning and polishing, the tops of the frets are marked to make sure the level of the frets are untouched by the recrowning files, as this would throw the level of the frets. Once the curve profile is filed into each fret, they are then hand polished to a shine, removing any file marks. The completed neck is cleaned and refitted to the guitar, so it can receive its setup with a fresh set of strings, then it's ready for the customer to collect!

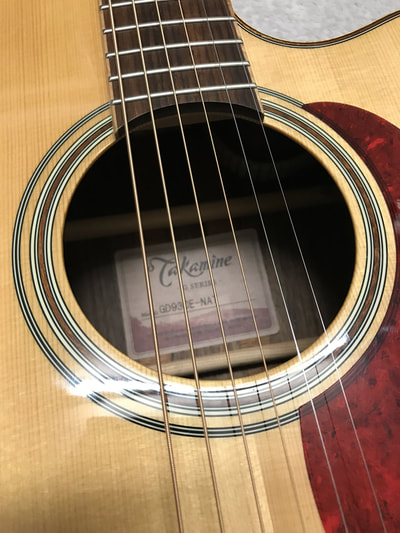

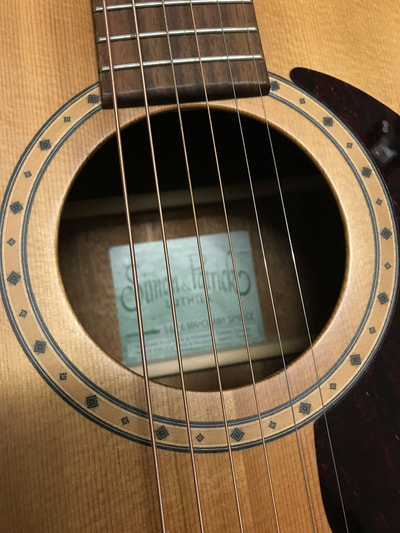

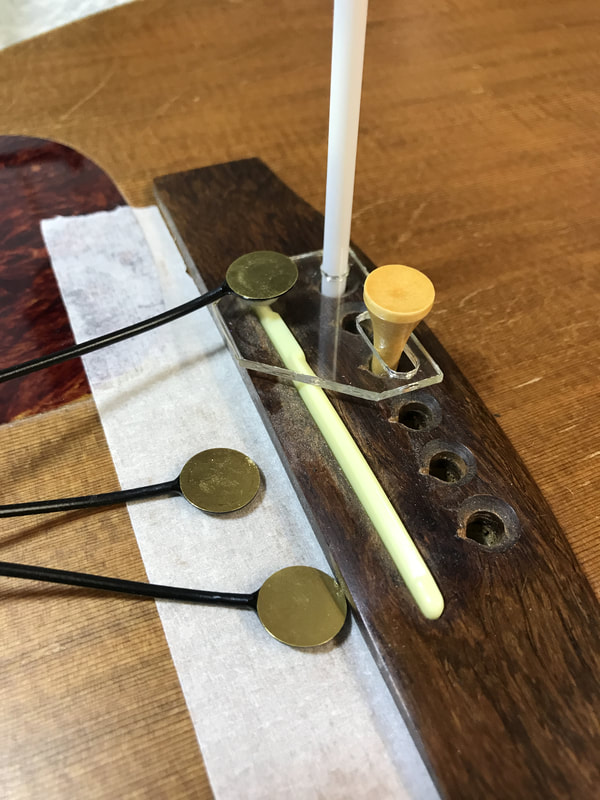

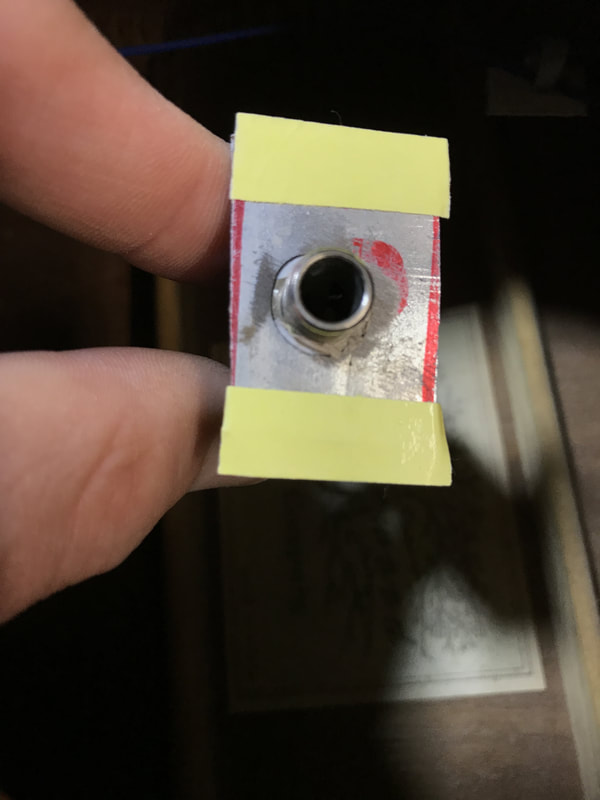

One of the jobs was replacing the saddle, which must of been swapped out at some stage. The current saddle was too small for the bridge, this affects tone transfer and the intonation as the saddle pulled forward in the slot. The new saddle was hand cut from a bone blank and shaped to fit, with the compensation for the intonation cut into the saddle. The bone saddle will also improve the tone of the guitar, by allowing better transfer of the strings energy to the soundboard when played. The K&K fitting involves having a end jacksocket hole drilled in the guitar, before the pickup transducers are carefully positioned. Using the supplied jig, the pickups are then glued underneath the bridge before the jacksocket is fitted. With all the work complete, the guitar was ready to be collected, the end result transformed the sound of the guitar and the way it played!

|

Lewis DurtnallHi, I'm Lewis, Ive been repairing guitars since 2004, I learnt my craft at Totnes School of Guitar Making! Archives

December 2022

Categories |

RSS Feed

RSS Feed