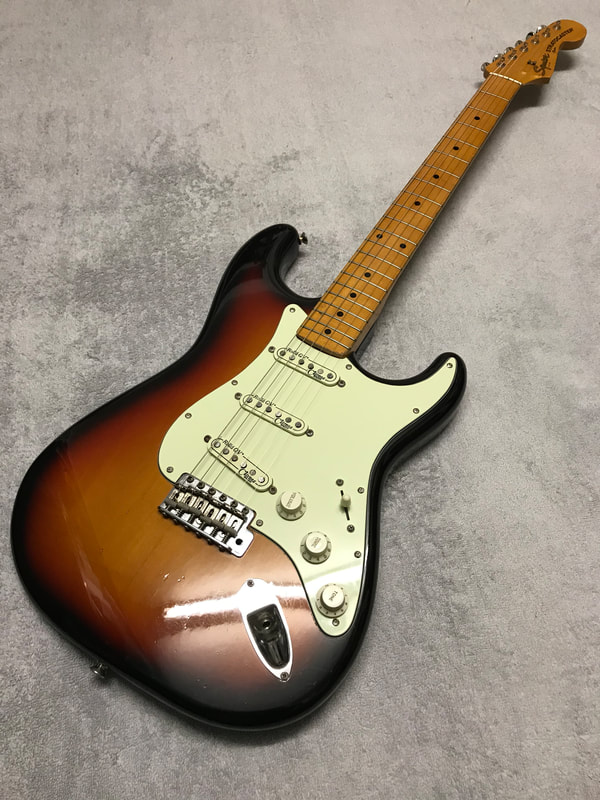

| Due to the Corona Social Lockdown, we've had our shortest month of trading. Here a few guitars that we had through the workshop before we had to close. The Fender Stratocaster had a killswitch toggleswitch fitted, the Les Paul Vintage was in for a full setup and the vintage Japanese Jazz Bazz was in to have it's pickup foam replaced and the height set. Although our workshop is closed, we are taking prebooking appointments, so as soon as we reopen we will be back working on guitars! Please get in touch if you're interested in having your guitar repaired/customised/restored! |

|

0 Comments

Updated Customer announcement:

Due to the Coronavirus outbreak, We’d like to reassure customers that the workshop is still open, and we are following government guidelines. Following the social distancing advice, we will only be operating an instrument drop off/ collection only at the workshop, from the doorway or outside (if weather allows). Please don't give us a strange look if we are wearing gloves and a spray mask. We are protecting the health of us and our customer. All work required will be confirmed by email, phone, text, Whatsapp or messenger. Don't forget we accept cash, card, payment and bank transfers so happy with whichever payment suits you best thanks. We kindly ask that any customers showing any suspected symptoms, please inform us and we can postpone your appointment. We thank you for your continued custom!

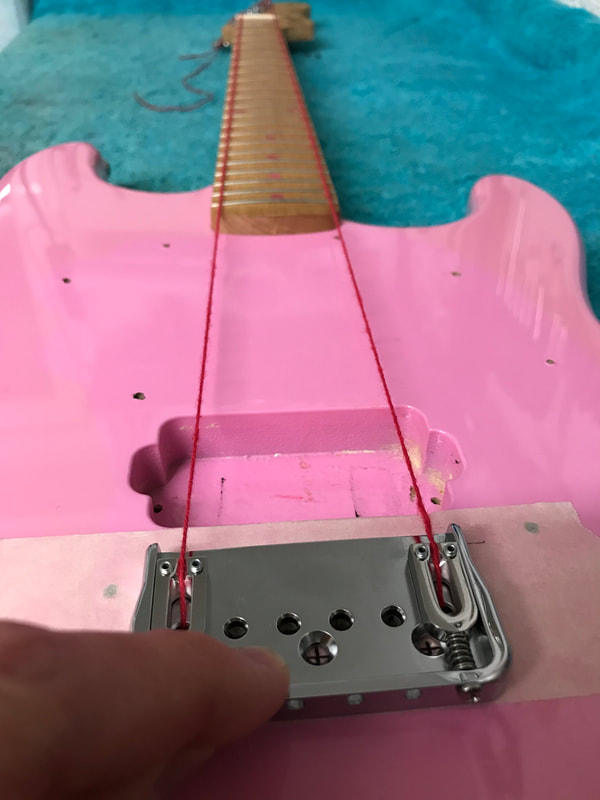

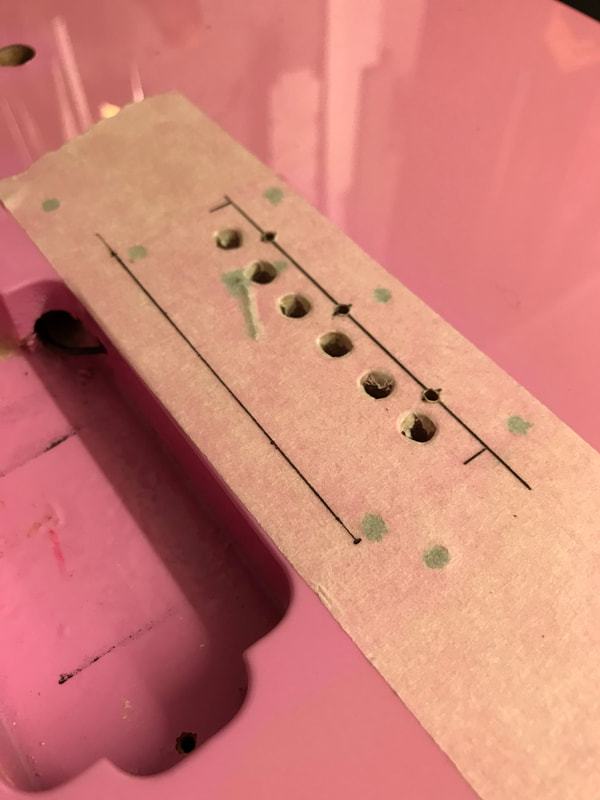

Checking the alignment of the new bridge before drilling holes. The holes marked out and drilled for the new bridge. We then plugged the old unused holes the next step was colouring matching them the best we could. The new bridge plate fitted with the new pickup fitted too.

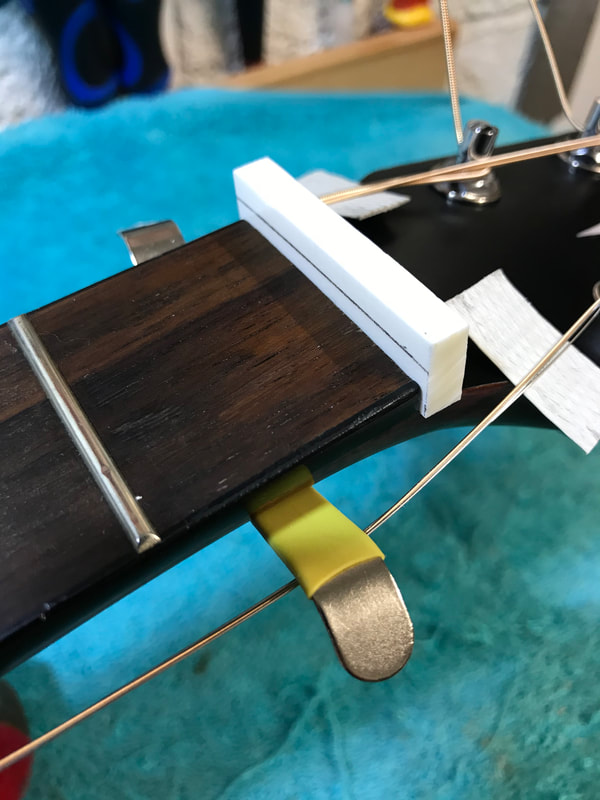

The nut slot was cleaned out before the new nut could be made. During the new nut cutting and shaping process the bone blank is cut to the exact size of the slot.

This lovely 6 string LTD bass was recently in the workshop to have it’s faulty jacksocket replaced with an uprated Switchcraft one!

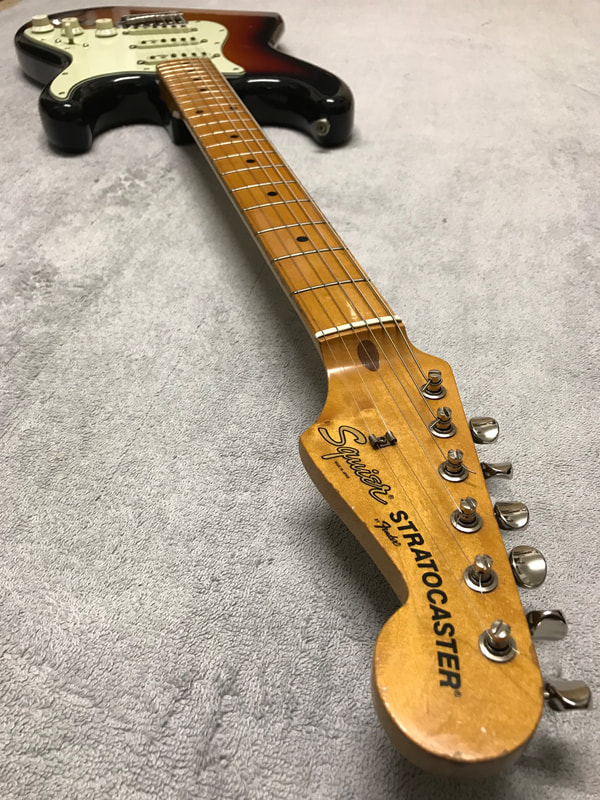

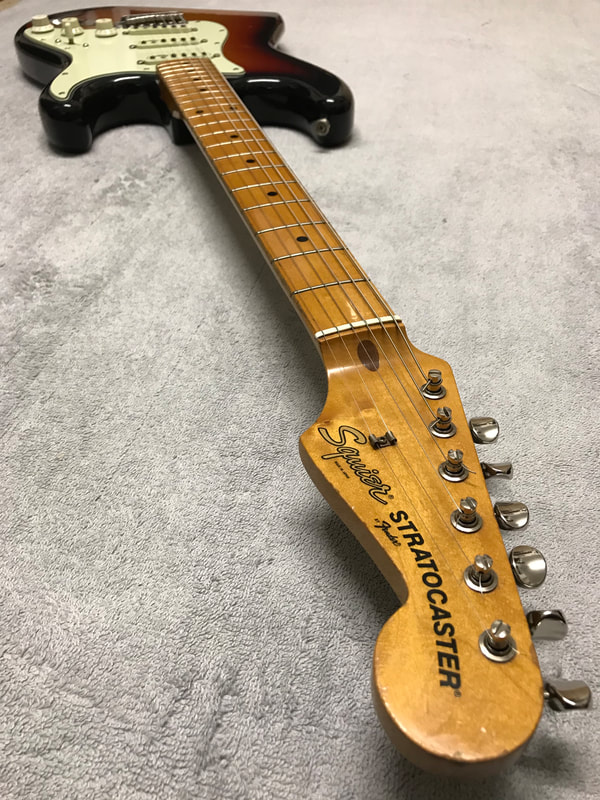

This ace 80's Japanese ‘JV serial number’ Squire Stratocaster was recently in the workshop for a mini restoration, including sorting noisy electronics, sorting worn saddles, along with fitting new locking Gotoh machineheads! The new locking machineheads have the exact same footprint as the vintage style originals. Very cleverly the locking pins are housed inside the post without changing the appearance of the vintage style tuner, we love those machineheads and have recommended them for years!

This poorly Cort acoustic was brought into the workshop with one of the worst headstock breaks we’ve seen! The break was repaired and refinished along with some wood inserts cut and fitted were tearout had caused holes in the neck! The customer also lost the nut so we cut and made a new bone nut matching the original, using the indents in the first fret as a guide for the string spacing! As the guitar was brought in, the break had also caused the fingerboard to start lifting away from the neck! The headstock being glued back on. After the gluing process the nut slot was cleaned as the top part of the break happened in the nut slot. Due to the damage, small chip outs of wood had broken off and had been lost before it was brought in for repair. These gaps needed to be sorted with new wood inserts. The gaps were opened up by hand carefully making it suitable for a wooden insert. The inserts were made by hand for an exact fit, then were glued and fitted before being made flush with the rest of the guitar neck. Another insert had to be made along the side of the neck where it made the fingerboard, here’s it’s already been made and fitted, and will be stained. The mahogany inserts smoothed back, the staining refinishing process could begin. Because of the damage with the fingerboard lifting, all down the neck had to be sanded to a smooth joint too so everything felt smooth to the touch. The staining process involved building up layers of a special stain, blending it in with the existing finish. The staining complete, with the lacquer also sprayed and then cut back to give a worn satin finish matching the rest of the body. We also touched up the chips on the sides of the front of the headstock, then refinished it with a satin lacquer to refresh the headstock. Below the process of making a new nut made. The bone nut is cut and shaped to an exact fit from a bone nut blank. The string slot spacings were worked out from the worn groove marks in the first fret, so the new nut would have the exact same string spacing as the original one. With all the work complete the guitar was restrung and ready for the customer to collect!

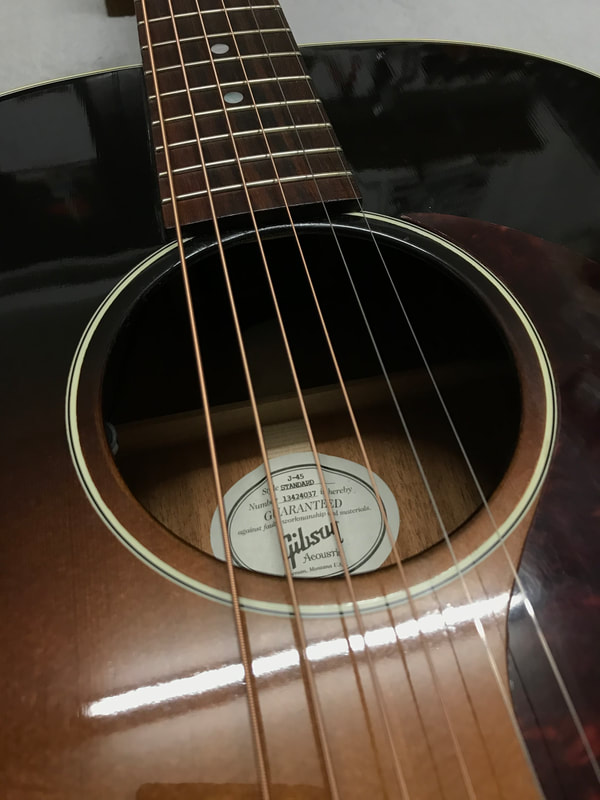

This lovely well gigged Gibson J45 was in the workshop for a new handcut bone nut and saddle, along with new bone bridge pins. This upgrade gave a new lease of life to the acoustic before going back out on the road gigging!

Along with the new bone bridge pins, the bone nut and saddle really transformed the tone of this lovely acoustic!

|

Lewis DurtnallHi, I'm Lewis, Ive been repairing guitars since 2004, I learnt my craft at Totnes School of Guitar Making! Archives

December 2022

Categories |

RSS Feed

RSS Feed