The work involved a new hand cut bone nut and saddle, new tusq bridge pins, new Gotoh machineheads, a hand fret polish, setup and a new custom scratchplate in the style of a Gibson one!

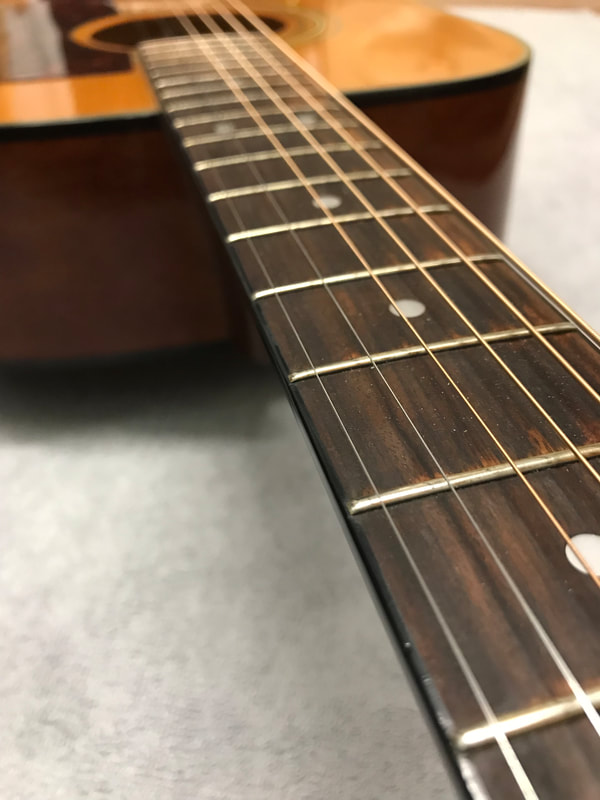

| The well played fretboard had years of gunk built up on it and the frets had become badly oxidized. The fingerboard was scrapped to remove all the gunk, before the board was masked off for the fret polish. The fret polish procedure involves the use of micro abrasvies, which bring the frets back to a mirror shine. Once the frets were polished, the board was cleaned and then lemon oiled, giving a new lease of life to the fingerboard |

The photos below show some stages of the process.

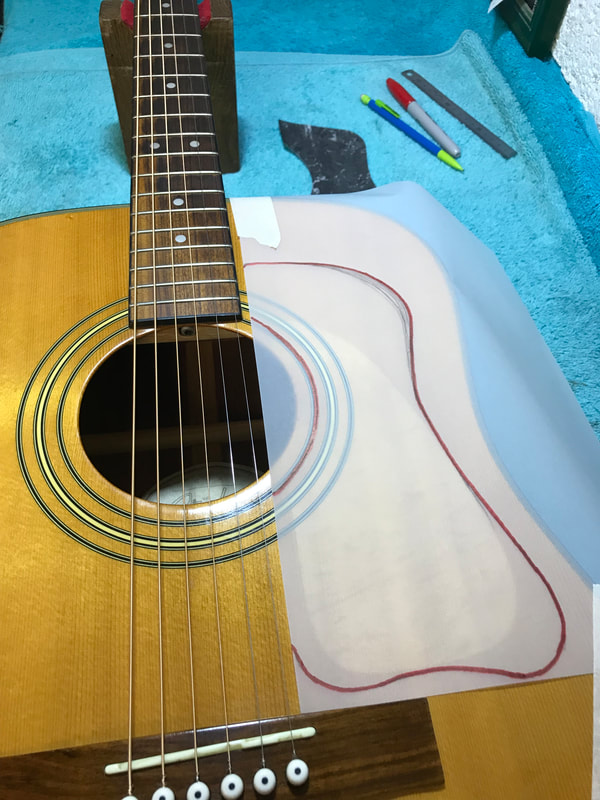

| The next part of the work, the customer wanted a new scratchplate, in the same style as a Gibson one (like the one pictured on the left) After checking dimensions it became clear that there wasn't one available that would fit, so a custom one would have to be cut and fitted, to give the customer the look he was after. |

Once the template shape was determined, the template is transferred onto a blank sheet of scratchplate plastic, where it is cut and shaped.

The final stage is the fitting on the guitar, carefully ensuring the position is correct while the adhesive backing is stuck down.

RSS Feed

RSS Feed