The break was repaired and refinished along with some wood inserts cut and fitted were tearout had caused holes in the neck!

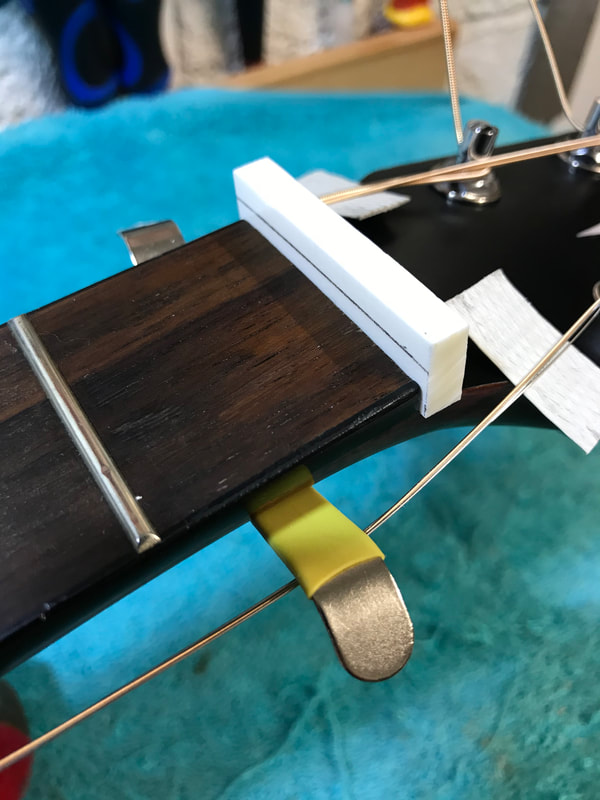

The customer also lost the nut so we cut and made a new bone nut matching the original, using the indents in the first fret as a guide for the string spacing!

The gaps were opened up by hand carefully making it suitable for a wooden insert.

Another insert had to be made along the side of the neck where it made the fingerboard, here’s it’s already been made and fitted, and will be stained.

The staining complete, with the lacquer also sprayed and then cut back to give a worn satin finish matching the rest of the body.

The string slot spacings were worked out from the worn groove marks in the first fret, so the new nut would have the exact same string spacing as the original one.

RSS Feed

RSS Feed