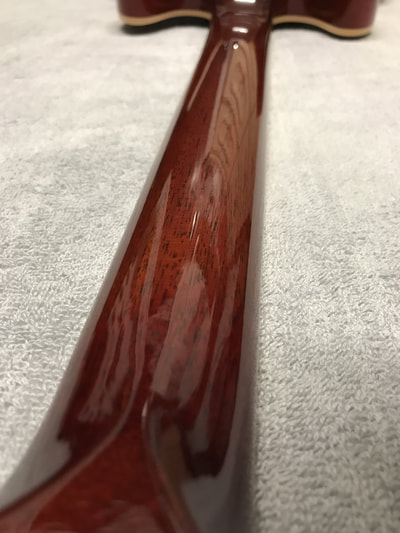

Once complete, the neck was then sprayed with Nitrocellulose lacquer, this blends in the existing Gibson lacquer, giving a smooth transition between lacquer coats. At the same time, the back of the headstock was sprayed too, evening out the slightly uneven factory finish. The lacquer was left for a set period of time to allow it to cure and sink before the flatting and polishing could begin.

|

This lovely Gibson Custom Shop 339 was brought in, as the guitar had suffered a headstock break. It had been repaired by a very well known guitar shop, however the customer wasn't happy with the poor refinishing attempt that the shop had done. As time went on he became more and more upset with the miscoloured repair to the point he stopped playing the guitar. Our job was to refinish the repair, hiding the work done by the previous repair shop. The first step was removing the mismatched red from the previous repair shop, once this was carefully removed, colour matched stain was then applied to the crack to blend the finish, hiding the crack in the process. Once complete, the neck was then sprayed with Nitrocellulose lacquer, this blends in the existing Gibson lacquer, giving a smooth transition between lacquer coats. At the same time, the back of the headstock was sprayed too, evening out the slightly uneven factory finish. The lacquer was left for a set period of time to allow it to cure and sink before the flatting and polishing could begin. Once the lacquer had been left to cure to a hardened state (Nitrocellouse never fully truly cures 100%, hence the tone of the wood is not sealed in) the lacquer was flattened back and then hand polished and buffed to a shine. The guitar was then restrung with a fresh set of strings before the customer collected his guitar!

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

Lewis DurtnallHi, I'm Lewis, Ive been repairing guitars since 2004, I learnt my craft at Totnes School of Guitar Making! Archives

December 2022

Categories |

RSS Feed

RSS Feed