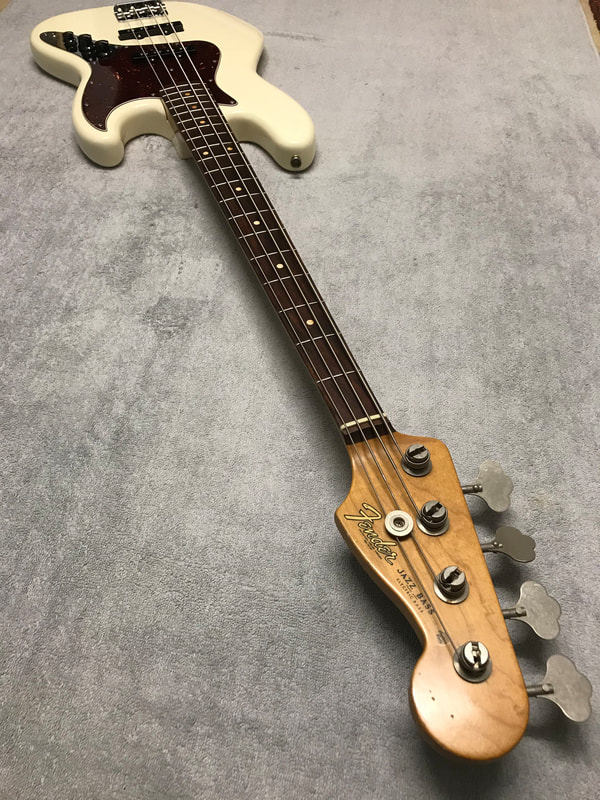

The first job was to sort the neck pocket on the brand new body, as the neck wouldn’t fit as it was slightly too wide for the pocket so the pocket was carefully opened up hand.

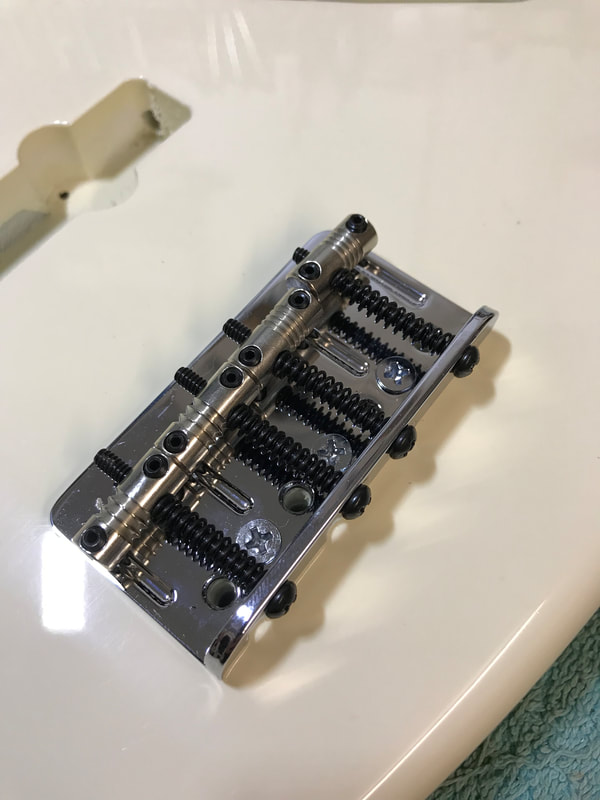

The Fender through strung bridge had to be specially sourced.

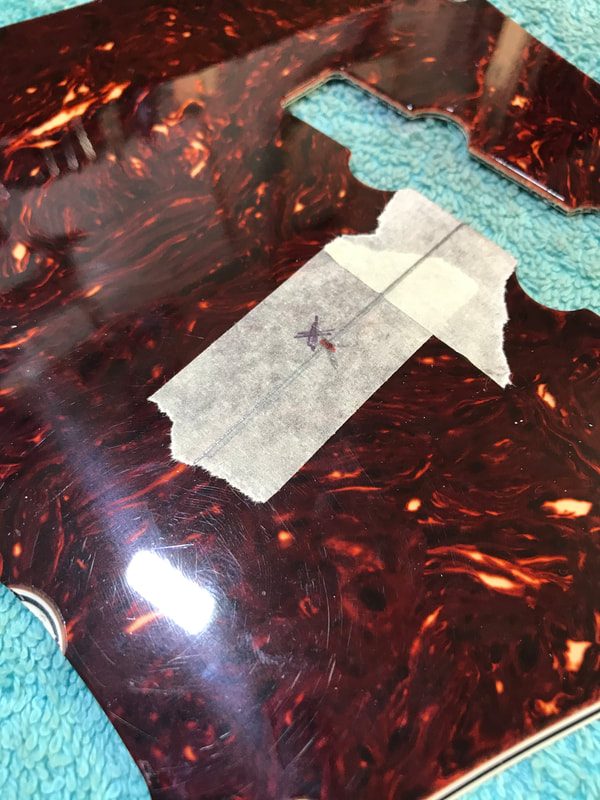

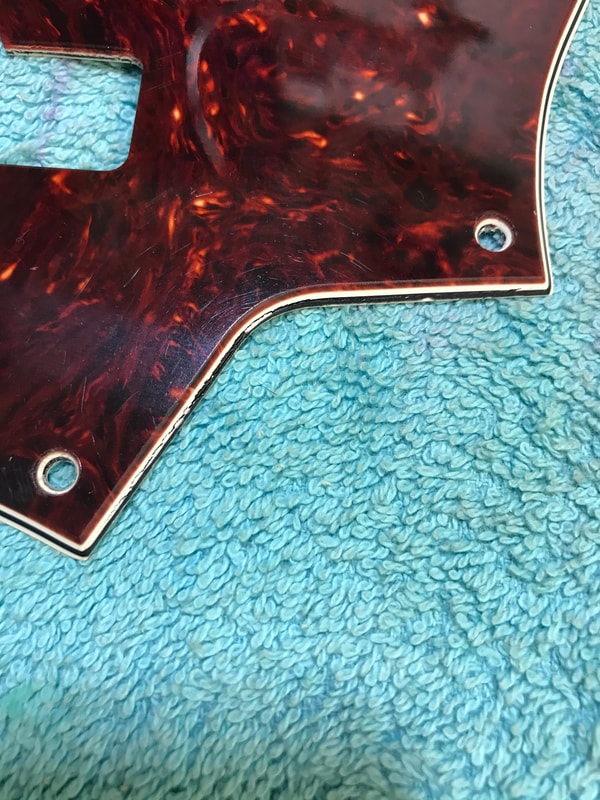

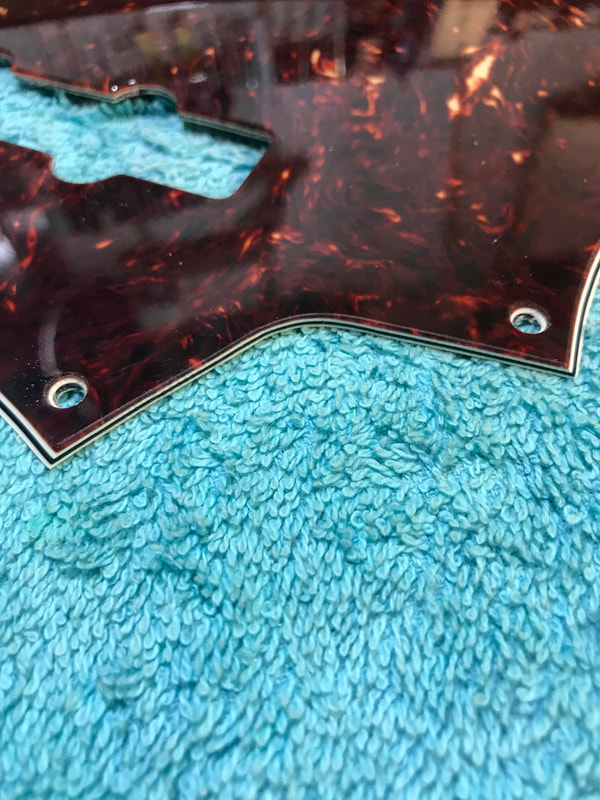

The customer wasn’t a fan of the bevelled edge where it met the control plate, So it was carefully hand filed to a straight edge allowing the control plate to be fitted right up against the scratchplate.

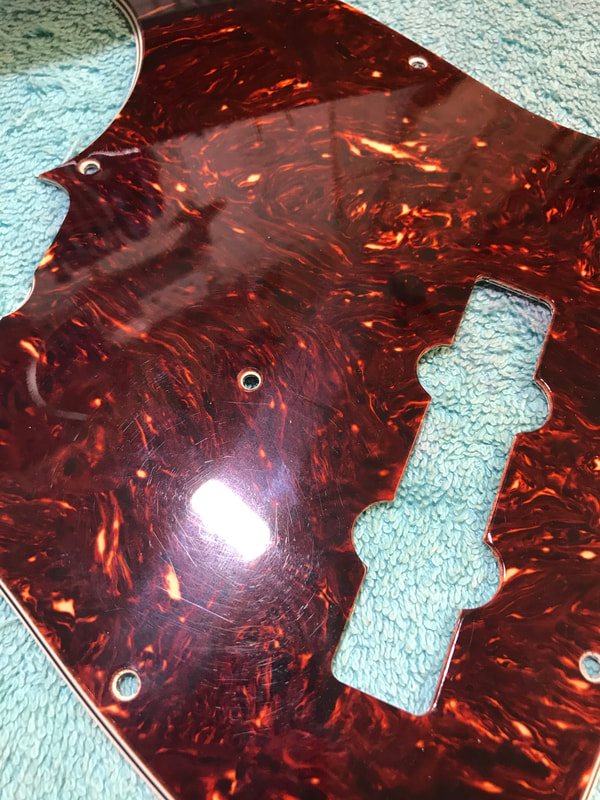

The cavity wasn’t deep enough for large CTS pots with the scratchplate and control plate used had to be made deeper at one section. The cavity was extended by hand with the notch to help path of the wires. Once done, the control was fitted.

RSS Feed

RSS Feed