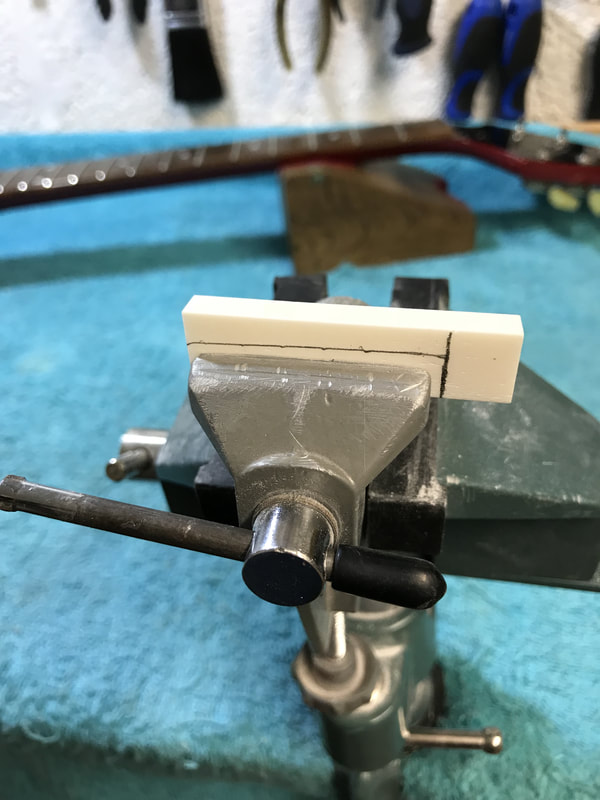

| This ace Tokai Flying V was brought into the workshop for a new nut and setup. The new nut was hand cut and shaped from bone, a massive improvement over the plastic one which was fitted on the guitar. Below shows the stages of the cutting process, at each stage, the fitment of the new nut is checked regularly to ensure the perfect fit on the guitar neck. The nut is profiled to the radius of the fingerboard and the slots are cut using the original nut as a guide, ensuring that the strings will follow the same path in case of fretwear. |

| With the new nut made, it's glued into position after being sanded to a smooth finish. All nut work is done completely by hand, this allows a degree of accuracy that cannot be achieved when using machines. The height of the string slots is purposely kept high until the nut has been glued in place. The slots are then cut down to set the action. Once the new nut was fitted, the guitar was setup to an ultra low action as requested by the customer. |

RSS Feed

RSS Feed